Through Hardening

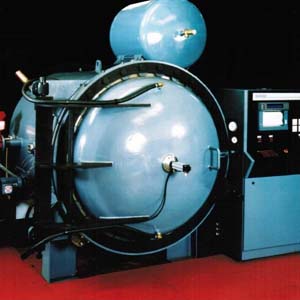

These are carried out in our vacuum furnaces, sealed quench or salt baths.

In layman's terms this is a process to make a high carbon steel harder or stronger or more wear resistant than in its stock condition. If this hardened steel was to be broken it would be as hard in the middle as it is on the outside.

Components are heated in our vacuum furnaces or one of our sealed quench furnaces or submerged into liquid salt to keep oxygen away from the component to prevent oxidization.

The through hardening material used dictates the hardening temperature we have to apply and the component size and thickness dictates the time we have to hold the component at temperature for.

Typically the hardening temperature ranges from 780°c to 1220°c which starts the transformation of the microstructure into austenite.

The austenitizing temperature is held for as little as a few minutes to maybe as long as a couple of hours to fully equalize the temperature and give full transformation of the microstructure to austenite.

The component then has to be quenched as rapidly as possible to retain the austenite. With our vacuum furnaces we use a nitrogen gas quench and if the component is heated in our sealed quench furnaces or salt pot it is quenched in oil.